We have extensive experience in designing and implementing test bench and measurement projects for various applications. In this section, we showcase some of the examples of our work, highlighting the graphical user interfaces and features that we have developed. We also provide details on the hardware and software components that we have used to create these solutions.

- TestStand: Car radio validation

The aim of this test bench is to validate electronic measurements and audio signals. The system must be enough flexible to permit the test of several models of car radio. Hardware Technology The bench is composed of: Software Technology Operating software : MS Windows XPMeasurement software : NI LabWindows/CVITest Sequencer : NI TestStandReports : MS Excel How does it work ? The operator connects the car radio to the interface which is connected to the test bench. He identifies the unit to be tested with the car radio bar code. The sequence test the sound quality, the consomation, the EEPROM software and… Read more: TestStand: Car radio validation

The aim of this test bench is to validate electronic measurements and audio signals. The system must be enough flexible to permit the test of several models of car radio. Hardware Technology The bench is composed of: Software Technology Operating software : MS Windows XPMeasurement software : NI LabWindows/CVITest Sequencer : NI TestStandReports : MS Excel How does it work ? The operator connects the car radio to the interface which is connected to the test bench. He identifies the unit to be tested with the car radio bar code. The sequence test the sound quality, the consomation, the EEPROM software and… Read more: TestStand: Car radio validation - LabWindows/CVI: Oil well sensors calibration system

Calibration system for oil well sensors. This system measures the pressure and the temperature behavior of the sensors along one week to one month. All measurements are safeguarded in a data base to be analyzed and to create reports/ratios. Hardware Technology The system is composed of a PC computer which dialogs with oil sensors via serial bus and it is linked to a bench via GPIB bus. The bench contains several modules : Software Technology Operating software : MS Windows 2000Measurement software : NI LabWindows/CVIAnalysis software : Visual Basic, MS ACCESS, ODBC, SQLReport formats : MS EXCEL, PDF How does it work ?… Read more: LabWindows/CVI: Oil well sensors calibration system

Calibration system for oil well sensors. This system measures the pressure and the temperature behavior of the sensors along one week to one month. All measurements are safeguarded in a data base to be analyzed and to create reports/ratios. Hardware Technology The system is composed of a PC computer which dialogs with oil sensors via serial bus and it is linked to a bench via GPIB bus. The bench contains several modules : Software Technology Operating software : MS Windows 2000Measurement software : NI LabWindows/CVIAnalysis software : Visual Basic, MS ACCESS, ODBC, SQLReport formats : MS EXCEL, PDF How does it work ?… Read more: LabWindows/CVI: Oil well sensors calibration system - LabVIEW vision: fuse box visual inspection for trucks

The fuses and relays box test bench has two functions in trucks assembly factory: Description The fuse inspection test bench consists of: The fuse inspection test bench works in two modes:

The fuses and relays box test bench has two functions in trucks assembly factory: Description The fuse inspection test bench consists of: The fuse inspection test bench works in two modes: - LabVIEW Real-Time: refrigeration system with two temperatures

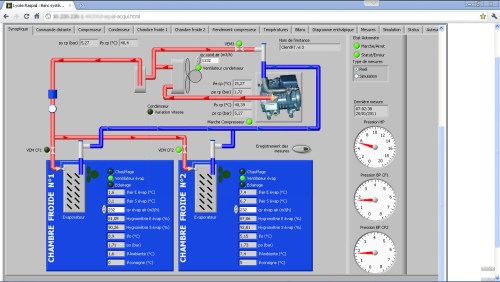

This system allows the study of refrigeration systems and the implementation of the thermodynamic calculations applied to refrigeration. Its uniqueness is that it is fully controllable via the Internet directly from a web browser like Internet Explorer or Firefox. It consists of two cold rooms, each with their own evaporator but sharing the same cooling fluid R134a system (compressor, condenser …). The control and configuration of this system can be done in two ways: The Compact Fieldpoint adds the possibility of remote control via the Internet, viewing the evolution curves of temperature, air and refrigerant fluid, pressure and power at various points. This allows calculating the required cooling system features such as enthalpy, entropy, Mollier diagram and performance coefficients. Hardware The software is embedded in a Compact Fieldpoint controller from National Instruments. It includes a RJ45 Ethernet connector that allows to connect to the network in aim of uploading the executable on the controller module to the embedded FTP and publish shared variables on the network. We use Compact Fieldpoint module inputs / outputs, analog and relays for sending commands (start / stop, compressor speed , refrigerant solenoid valves, condenser and evaporator fans, lights and heaters for cold rooms) and collect measurements. We measure the power consumed by the compressor with the power meter included in the regulator. This regulator communicates only by Jbus protocol. So we use the RS-232 Compact Fieldpoint controller and connect to it an RS-232 <-> RS-485 converter. Jbus communication functions are programmed into the controller based on the Modbus protocol that is compatible for our use. An Ethernet 8 relays card is added to increase the number of relays. Software How does it work? The user has the option to choose, by a switch, using the bench in local mode with the classical control panel or using… Read more: LabVIEW Real-Time: refrigeration system with two temperatures

This system allows the study of refrigeration systems and the implementation of the thermodynamic calculations applied to refrigeration. Its uniqueness is that it is fully controllable via the Internet directly from a web browser like Internet Explorer or Firefox. It consists of two cold rooms, each with their own evaporator but sharing the same cooling fluid R134a system (compressor, condenser …). The control and configuration of this system can be done in two ways: The Compact Fieldpoint adds the possibility of remote control via the Internet, viewing the evolution curves of temperature, air and refrigerant fluid, pressure and power at various points. This allows calculating the required cooling system features such as enthalpy, entropy, Mollier diagram and performance coefficients. Hardware The software is embedded in a Compact Fieldpoint controller from National Instruments. It includes a RJ45 Ethernet connector that allows to connect to the network in aim of uploading the executable on the controller module to the embedded FTP and publish shared variables on the network. We use Compact Fieldpoint module inputs / outputs, analog and relays for sending commands (start / stop, compressor speed , refrigerant solenoid valves, condenser and evaporator fans, lights and heaters for cold rooms) and collect measurements. We measure the power consumed by the compressor with the power meter included in the regulator. This regulator communicates only by Jbus protocol. So we use the RS-232 Compact Fieldpoint controller and connect to it an RS-232 <-> RS-485 converter. Jbus communication functions are programmed into the controller based on the Modbus protocol that is compatible for our use. An Ethernet 8 relays card is added to increase the number of relays. Software How does it work? The user has the option to choose, by a switch, using the bench in local mode with the classical control panel or using… Read more: LabVIEW Real-Time: refrigeration system with two temperatures - LabVIEW: Weather station with a Pocket PC

The purpose of this system is the collection of weather data, backup and transmission to the base located 5 km away. The system is portable and durable for outdoor use (rain, dust …). Hardware Technology The system is composed of : Software Technology PC operating software : MS Windows XPPocket PC operating software : MS Windows CEMeasurement software : NI LabVIEW Pocket PC and NI LabVIEW on the PC How does it work ? The operator connects the suitcase to the weather station. He opens the suitcase, switches on the Pocket PC and selects, via its touch screen, to transmit data.The weather station sent… Read more: LabVIEW: Weather station with a Pocket PC

The purpose of this system is the collection of weather data, backup and transmission to the base located 5 km away. The system is portable and durable for outdoor use (rain, dust …). Hardware Technology The system is composed of : Software Technology PC operating software : MS Windows XPPocket PC operating software : MS Windows CEMeasurement software : NI LabVIEW Pocket PC and NI LabVIEW on the PC How does it work ? The operator connects the suitcase to the weather station. He opens the suitcase, switches on the Pocket PC and selects, via its touch screen, to transmit data.The weather station sent… Read more: LabVIEW: Weather station with a Pocket PC - LabVIEW: supervisor of sand quality control

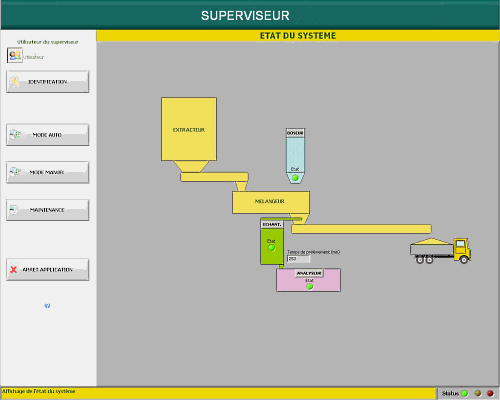

LabVIEW is used in this system to program a supervisor controlling the quality of sand in a career, before filling the trucks after the results of measurements of quality, we will inject a product to improve the characteristics of the sand to neutralize impurities (such as clay for example) and make them suitable for building. This pilot supervises three PLC (programmable logic controller), which each have a dedicated function: a sampler, a analyser and a divider. Programmable logic controller Hardware technology The excavation and filling trucks is completed by the sampler, analyzer and dozer system, wich is composed of: Software technology Operating system:… Read more: LabVIEW: supervisor of sand quality control

LabVIEW is used in this system to program a supervisor controlling the quality of sand in a career, before filling the trucks after the results of measurements of quality, we will inject a product to improve the characteristics of the sand to neutralize impurities (such as clay for example) and make them suitable for building. This pilot supervises three PLC (programmable logic controller), which each have a dedicated function: a sampler, a analyser and a divider. Programmable logic controller Hardware technology The excavation and filling trucks is completed by the sampler, analyzer and dozer system, wich is composed of: Software technology Operating system:… Read more: LabVIEW: supervisor of sand quality control - Automation Software for Clinical Testing of Cosmetic and Pharmaceutical Products

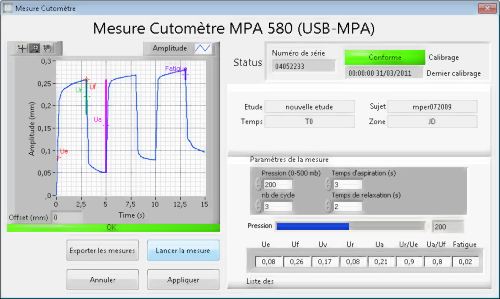

An Innovative Solution Developed by AJOLLY Testing for Monaderm Clinical Lab Software was developed by AJOLLY Testing, a specialist in test and measurement solutions, for Monaderm, a leading provider of technologies for clinical studies on cosmetic and pharmaceutical products. This software automates skin characterization measurements, streamlining the evaluation of dermatological product efficacy while ensuring precision and full traceability throughout clinical studies. Thanks to its integration with a wide range of measurement instruments, Clinical Lab Software optimizes laboratory workflows by reducing data collection time and eliminating manual errors. ⚙️ Key Features 🧪 Compatible Instruments Clinical Lab Software supports industry-standard equipment used… Read more: Automation Software for Clinical Testing of Cosmetic and Pharmaceutical Products

An Innovative Solution Developed by AJOLLY Testing for Monaderm Clinical Lab Software was developed by AJOLLY Testing, a specialist in test and measurement solutions, for Monaderm, a leading provider of technologies for clinical studies on cosmetic and pharmaceutical products. This software automates skin characterization measurements, streamlining the evaluation of dermatological product efficacy while ensuring precision and full traceability throughout clinical studies. Thanks to its integration with a wide range of measurement instruments, Clinical Lab Software optimizes laboratory workflows by reducing data collection time and eliminating manual errors. ⚙️ Key Features 🧪 Compatible Instruments Clinical Lab Software supports industry-standard equipment used… Read more: Automation Software for Clinical Testing of Cosmetic and Pharmaceutical Products - LabVIEW: Electronic Control Module (ECM) validation system

Electronic Control Modules are subsystems consisting of CPUs and assorted signal inputs and outputs dedicated to controlling a component within the vehicle (cars, trucks…).The aim of this system is to check that all ECM actions are correct, conforming to the specifications. It performs design validation.It is a development bench, helping technicians and developers during design and developement phases. Hardware Technology The bench is composed of : Software Technology Operating software : MS Windows XPMeasurement software : NI LabVIEW, NI DAQ How does it work ? Using the measurement software, the operator selects stimuli to be sent to the ECM. Each ECM response… Read more: LabVIEW: Electronic Control Module (ECM) validation system

Electronic Control Modules are subsystems consisting of CPUs and assorted signal inputs and outputs dedicated to controlling a component within the vehicle (cars, trucks…).The aim of this system is to check that all ECM actions are correct, conforming to the specifications. It performs design validation.It is a development bench, helping technicians and developers during design and developement phases. Hardware Technology The bench is composed of : Software Technology Operating software : MS Windows XPMeasurement software : NI LabVIEW, NI DAQ How does it work ? Using the measurement software, the operator selects stimuli to be sent to the ECM. Each ECM response… Read more: LabVIEW: Electronic Control Module (ECM) validation system - LabVIEW: test bench for gas analysis

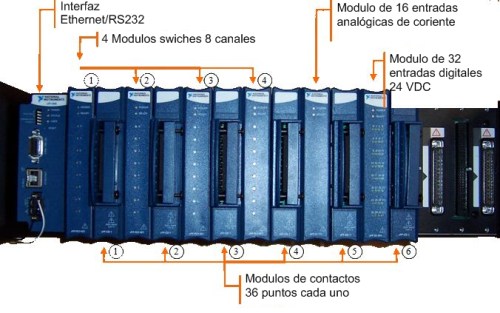

The role of this test bench is the analysis and quality control of gas cylinders used in metallurgical industries, chemical, petrochemical, pharmaceutical and food industry. The control system of gas is functionally decomposed as follows: The bench contains the following elements: Harware technology The supervision software is installed on a PC. The acquisition and control central is composed of Compact Fieldpoint modules of National Instruments. Gas analyzers are Emerson Process. The supervisor, on the PC, is linked to central by a serial link (RS232). The central commands 0/24V switches to route gas to the analyzer. The central commands analyzers by 4-20mA. Software… Read more: LabVIEW: test bench for gas analysis

The role of this test bench is the analysis and quality control of gas cylinders used in metallurgical industries, chemical, petrochemical, pharmaceutical and food industry. The control system of gas is functionally decomposed as follows: The bench contains the following elements: Harware technology The supervision software is installed on a PC. The acquisition and control central is composed of Compact Fieldpoint modules of National Instruments. Gas analyzers are Emerson Process. The supervisor, on the PC, is linked to central by a serial link (RS232). The central commands 0/24V switches to route gas to the analyzer. The central commands analyzers by 4-20mA. Software… Read more: LabVIEW: test bench for gas analysis